Willkommen

Mit über 60 Jahren Erfahrung und vielen Weltmarktführern als Kunden, sind wir Ihr zuverlässiger Partner in Sachen Thermoforming, CNC-Bearbeitung und Montage.

Alles aus einer Hand

Als verarbeitender Betrieb mit mehr als 60 Jahren Marktpräsenz haben wir uns als kontinuierlicher und leistungsstarker Partner in der Kunststoff Branche am Markt etabliert.

Unser Fokus liegt auf Fairness, Professionalität und Qualität. Wir begleiten Sie bei Ihrem Vorhaben! Von der Projektplanung, über Entwicklung bis hin zur Fertigung geben wir Ihren Visionen neue Impulse.

Partner bedeutender Weltmarktführer

Ein starkes Team.

Unser hochmoderner Maschinenpark wird von unseren bestens ausgebildeten und geschulten Mitarbeitern bedient. So sind wir in der Lage Ihnen jegliche Wünsche in den Bereichen Kunststoff-Tiefziehen, Kunststoffspritz- & Zinkdruckguss (inkl. eigenem Werkzeugbau) sowie verschiedenen Veredelungsarbeiten, zu erfüllen.

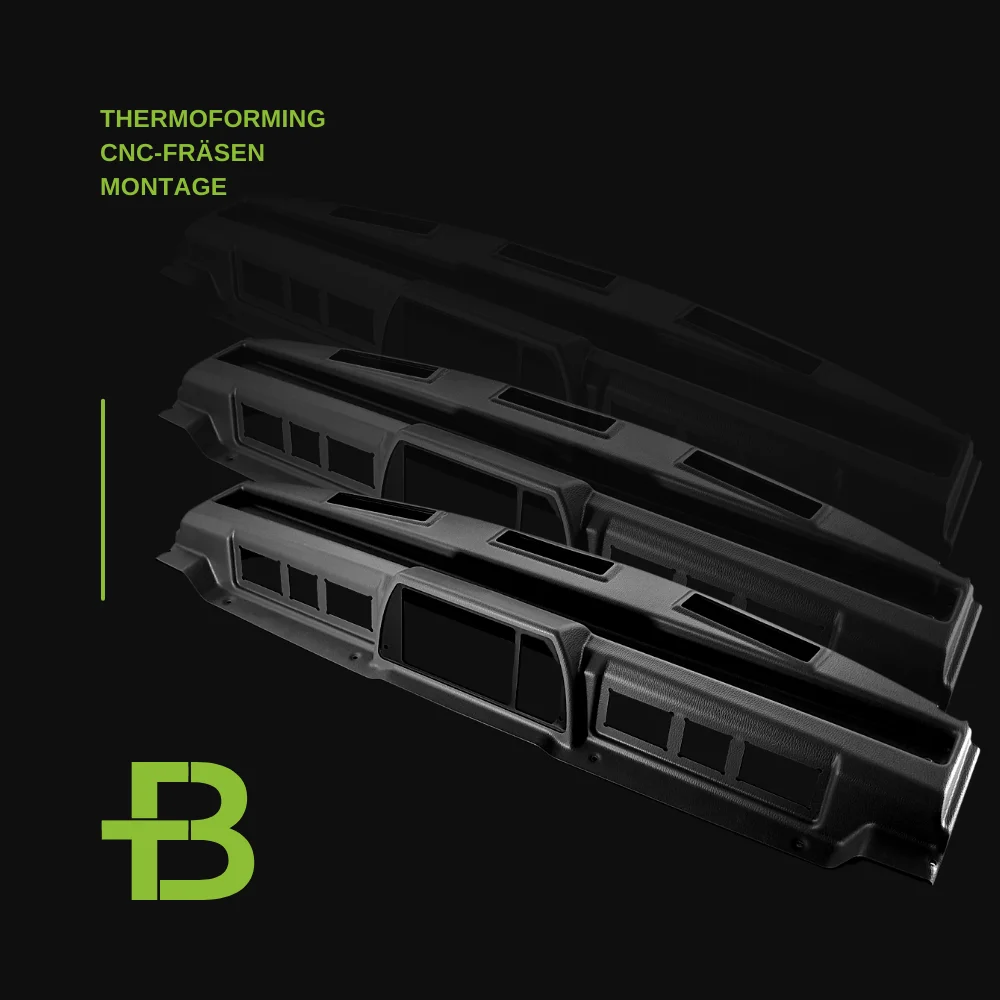

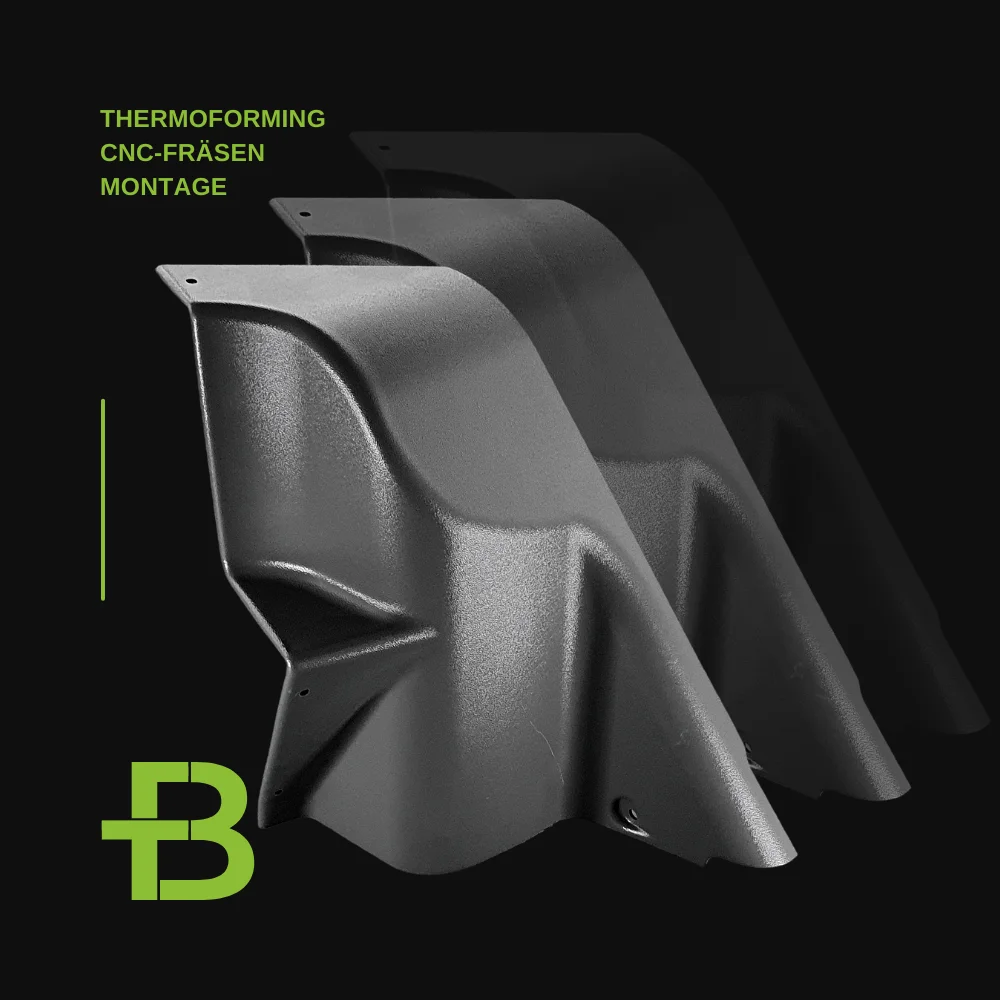

Thermoforming – Tiefziehen

Unsere Kernkompetenz ist das sogenannte Tiefziehen, auch bekannt als Vakuumformung oder Thermoforming – auch von große Kunststoffteilen.

Auf unseren neun hochmodernen Tiefziehanlagen, verarbeiten wir alle gängigen Thermoplasten bis zu einer Plattengröße von 3300 x 2300 mm und einer Plattenstärke bis 20 mm.

CNC-Fräsen

Mit unseren sieben 5-Achs-CNC-Fräszentren realisieren wir die anspruchsvollsten Bauteile mit einer maximalen Größe von 3.300 x 2.300 x 1.000mm.

So können wir mit einer Maßhaltigkeit von 0,2mm nahezu jede Toleranz einhalten. Sollte dies dennoch nicht ausreichend sein, prüfen wir Ihre Anfrage gerne im Spritzguss.

Selbes Bauteil, anderer Beschnitt? Auch das stellt uns vor keine Herausforderung dar. Durch verschiedene Programme lassen sich unterschiedliche Bauteilvarianten umsetzen und das bei minimalem Aufwand.

Montage

Durch verschiedene Fügeprozesse (verschrauben, verschweißen, verkleben) lassen sich komplexe Baugruppen umsetzen. Welcher der richtige ist, eruieren wir bei einem gemeinsamen Gespräch.

Dabei können Sie entscheiden, ob Sie die Beschaffung übernehmen oder diese an uns outsourcen und sich auf Ihre Kernkompetenzen fokussieren möchten.

Unsere Branchen

Automotive

Funktionalität und Sicherheit als oberste Maxime.

Medizintechnik

Hygienisch und funktional für Medizin und Labor.

Logistik

Für funktionale, effiziente und sichere Transporte.

Weitere

Mit makellosen Oberflächen ganz nach Ihrem Geschmack.

Nachhaltigkeit

In Zusammenarbeit mit führenden Spezialisten der Biopolymer-Forschung haben wir Kunststoffe auf Basis nachwachsender Rohstoffe (Lignin) in unser Fertigungsverfahren integriert.

Know-how und Erfahrung aus mehr als 100 Jahren

Die Firmengründung durch Julius Bauer, den Namensgeber des heutigen Unternehmens, datiert in das Jahr 1905 zurück. Fünf Jahrzehnte später wurde das Unternehmen um den Geschäftsbereich Vakuum-Tiefziehen erweitert. Zur Jahrtausendwende folgte das Twin-Sheet-Verfahren, und seit 2010 verarbeiten wir bio-basierte Thermoplaste.